Leha e tsoetse pele haholo mabapi le boleng ba sehlahisoa le boiketsetso ba tlhahiso ha e bapisoa le mekhoa ea ho kenya le ho betla, ho ntse ho e-na le mefokolo e mengata katlehong ea phapanyetsano ea mocheso le thibelo ea ho bokellana ha molora oa lipeipi tse nang le mapheo a moholisitsoeng ka makhetlo a mangata ka lebaka la mabaka a kang bothata ba ho tjheseletsa metsong ea lipeipi tse nang le mapheo a moholisitsoeng ka makhetlo a mangata le maqeba metsong.

Phaephe e nang le mapheo ke mofuta oa karolo ea phapanyetsano ea mocheso. E le ho ntlafatsa katleho ea phetisetso ea mocheso, bokaholimo ba phaephe ea phapanyetsano ea mocheso hangata bo eketsoa ka ho eketsa mapheo ho eketsa sebaka sa bokaholimo ba kantle (kapa sebaka sa bokaholimo ba kahare) ba phaephe ea phapanyetsano ea mocheso, e le ho fihlela sepheo sa ho ntlafatsa katleho ea phetisetso ea mocheso, phaephe e joalo ea phapanyetsano ea mocheso.

Jwalo ka karolo ya phapanyetsano ya mocheso, phaephe e nang le finned e sebetsa tlasa maemo a kgase e nang le mocheso o phahameng ka nako e telele, jwalo ka sehokelo sa mocheso sa boiler se nang le finned tube tikolohong e thata, mocheso o phahameng le kgatello le sepakapakeng se senyang, e leng se hlokang hore phaephe e nang le finned e be le matshwao a tshebetso e phahameng.

1), Thibelo ea ho bola

2), Thibelo ea ho roala

3), khanyetso e tlase ea ho kopana

4), Botsitso bo Phahameng

5), Bokhoni ba ho bokella lerōle

Melemo ea mapheo a spiral a tšepe e sa hloekang a welded ka laser.

1. Ka ho sebedisa theknoloji ya ho tjheseletsa ka laser ya pulse, ho tjheseletsa ho potoloha sengoathoana ho phethelwa ka nako e le nngwe, mme sekgahla sa ho tjheseletsa sa sengoathoana sa tube se fihla ho 100%.

2. Ho tjheseletsa ka laser ke motsoako oa tšepe, matla a ho tjheseletsa a lakane ea tube a ka fihla ho feta 600MPa.

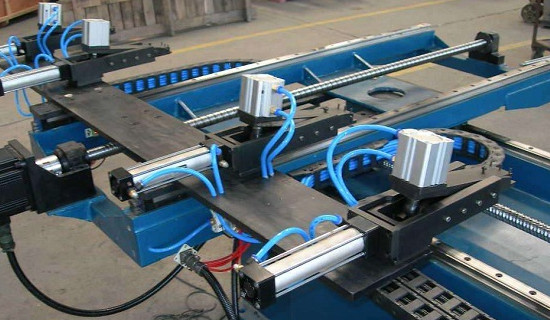

3. Mochini oa ho tjheseletsa oa laser o amohela sistimi ea phetisetso ea servo, ho nepahala ha phetisetso ho ka fihla boemong ba Kumi.

4. Sebaka sa karolo ea tube ea ho tjheseletsa ea laser e ka ba ≤ 2.5mm, sebaka sa ho qhalana ha mocheso ho feta tube ea ho tjheseletsa ea maqhubu a phahameng (sebaka sa karolo ≥ 4.5mm) se eketsehile ka hoo e ka bang 50%, e leng se fokotsang lintho tse sebelisoang ka sebaka sa yuniti, se ka fokotsa haholo bophahamo ba mokena-lipakeng oa mocheso.

Nako ea poso: Loetse-30-2022