SMAC e fana ka disete tse felletseng tsa disebediswa bakeng sa mela ya ho penta ka spray, mela ya ho kwahela phofo, mela ya electrophoresis, mela ya anodizing, kalafo ya pele ho nako, tlhoekiso, ho omisa le ho phekola, ho tsamaisa, le kalafo ya kgase le metsi a ditshila. Dihlahiswa tsa SMAC di sebediswa haholo diindastering tse kang tsa dikoloi, dithuthuthu, dikarolo tsa baesekele, dihlahiswa tsa IT, dihlahiswa tsa 3C, disebediswa tsa lapeng, thepa ya ka tlung, dijana tsa ho pheha, thepa ya moaho e kgabisitsweng, le mechini ya kaho.

Kamora hore sesebediswa se tswe ka ontong e hlwekisang, se kena tsamaisong ya ho phodisa ka potlako bakeng sa kalafo ya ho phodisa.

Ho koahela ka motlakase ho kenyelletsa ho sebelisa tšimo ea motlakase ea kantle ho hasanya likaroloana tsa pente tse nang le ion tse leketlileng ka metsing, ho li lumella ho koahela bokaholimo ba mosebetsi le ho etsa lera le sireletsang. Ts'ebetso ena e na le melemo e 'maloa:

Ho Koahela ka Tsela e Tšoanang: Ho koahela ho sebelisoa ka ho lekana holim'a bokaholimo.

Ho khomarela ka matla: Pente e khomarela hantle mosebetsing.

Tahlehelo e Nyenyane ea Pente: Ho na le tšenyo e nyane ea thepa ea ho roala, e leng se lebisang ho sekhahla se phahameng sa tšebeliso.

Litšenyehelo tse Tlase tsa Tlhahiso: Litšenyehelo ka kakaretso tsa tlhahiso lia fokotseha.

Ho Hlapolloa ho Thehiloeng Metsing: Pente e ka hlapolloa ka metsi, e leng se felisang likotsi tsa mollo le ho ntlafatsa polokeho nakong ea tlhahiso.

Likarolo tsena li etsa hore ho roala ka electrophoretic e be khetho e tsebahalang liindastering tse fapaneng.

Sesebelisoa sa ho sefa ka ho feteletseng (UF) se na le haholo-holo di-module tsa lera, dipompo, diphaephe le disebediswa, tsohle di kopantswe mmoho. Ho netefatsa tshebetso e tlwaelehileng ya yuniti ya ho sefa ka ho feteletseng, hangata e na le ditsamaiso tsa ho sefa le ho hlwekisa. Morero o ka sehloohong ke ho eketsa bophelo ba tshebetso ya tharollo ya pente, ho ntlafatsa boleng ba ho roala, le ho netefatsa hore palo e hlokahalang ya ho sefa ka ho feteletseng bakeng sa tshebetso e tlwaelehileng ya disebediswa.

Sistimi ea ho sefa ka bongata e etselitsoe ho ba sistimi ea potoloho e tobileng: pente ea electrophoretic e tlisoa ka pompo ea phepelo ho ea sefeng sa pele sa sistimi ea ho sefa ka bongata bakeng sa 25 μs ea kalafo ea pele. Kamora sena, pente e kena yuniti e kholo ea sistimi ea ho sefa ka bongata, moo karohano ea metsi e etsahalang ka module ea lera. Pente e kopaneng e arotsoeng ke sistimi ea ho sefa ka bongata e khutlisetsoa tankeng ea electrophoretic ka liphaephe tsa pente e kopaneng, ha ultrafiltrate e bolokoa ka tankeng ea polokelo ea ultrafiltrate. Ultrafiltrate ka tankeng ea polokelo e fetisetsoa moo e sebelisoang ka pompo ea phetisetso.

Mokotla oa ho Futhumatsa - Ho Baka le ho Hloekisa

Mokotla o futhumatsang o sebediswa tshebetsong ya ho baka le ho lokisa dikobo, haholoholo diindastering tse kang tsa dikoloi le tsa tlhahiso. Kakaretso ke ena:

1. Mosebetsi: Mokotlana o futhumatsang o fana ka mocheso o laolwang ho di-workpiece tse manehilweng, o thusa ho lokisa pente kapa di-coat tse ding. Sena se netefatsa hore coat e kgomarela hantle mme e fihlella boima le ho tshwarella ho lakatsehang.

2. Moralo: Mekotla e futhumatsang hangata e etsoa ka thepa e sa keneleng mocheso mme e etselitsoe ho aba mocheso ka ho lekana holim'a likarolo tsa mosebetsi.

3. Taolo ea Mocheso: Hangata li tla le litsamaiso tsa taolo ea mocheso tse hahiloeng kahare ho boloka mocheso o hlokahalang oa ho folisa, ho netefatsa liphetho tse tsitsitseng.

4. Bokgoni: Ho sebedisa mokotla wa ho futhumatsa ho ka fokotsa tshebediso ya matla ha ho bapiswa le dionto tsa setso, kaha ho ka tsepamisa mocheso ka ho toba dikarolong tse phekolwang.

5. Ditshebediso: E sebediswa hangata ditshebetsong tsa ho penta ka phofo, ho penta ka electrophoretic, le ditshebedisong tse ding moo ho hlokahalang qetello e tshwarellang.

Mokhoa ona o ntlafatsa boleng ba sehlahisoa se felileng ha ka nako e ts'oanang o netefatsa tšebeliso e ntle ea lisebelisoa.

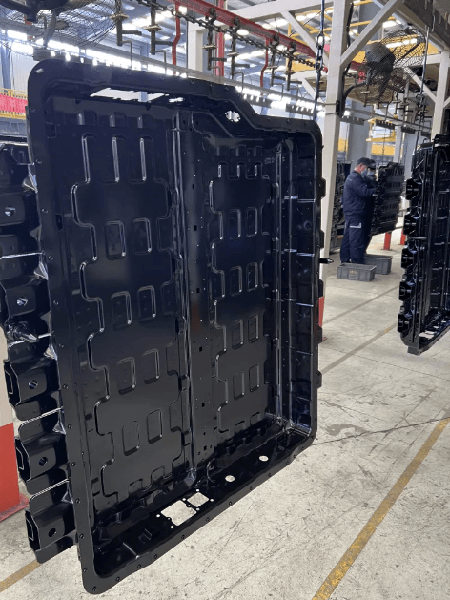

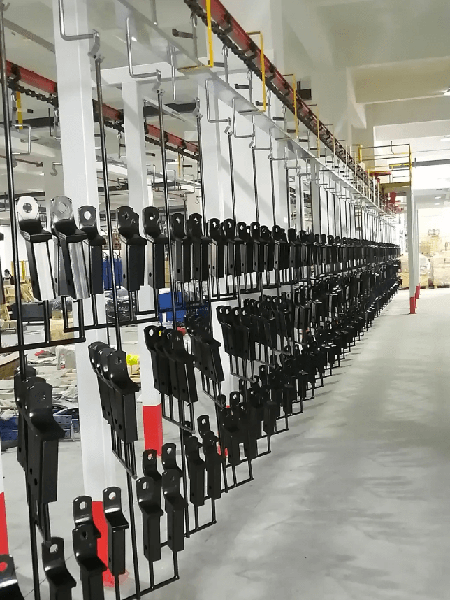

Sistimi ea ho Fetisa

Sistimi ea ho tsamaisa thepa e ka holimo e na le likarolo tse 'maloa tsa bohlokoa, ho kenyeletsoa le mokhoa oa ho khanna, sesebelisoa sa ho tiisa se nang le boima, liketane, litsela tse otlolohileng, litsela tse kobehileng, litsela tsa telescopic, litsela tsa tlhahlobo, litsamaiso tsa ho tlotsa, litšehetso, li-hangers tse jarang mojaro, litsamaiso tsa taolo ea motlakase, le lisebelisoa tsa tšireletso ea ho feteletsa lintho. Mesebetsi ea eona ea mantlha ke e latelang:

1. Tshebetso: Ha enjene e potoloha, e kganna dipina ka hara reducer, e leng se matlafatsang ketane yohle ya conveyor e ka hodimo. Di-workpiece di leketliswa ho conveyor ho sebediswa mefuta e fapaneng ya di-hangers, e leng se nolofatsang ho tshwarwa le ho sebediswa ha tsona habonolo.

2. Ho iketsetsa: Sebopeho sa mohala wa conveyor se laolwa ke tikoloho e ikgethang ya mosebetsi le phallo ya tshebetso ya sehlahiswa, e fihlelang ditlhoko tsa tlhahiso ka katleho.

3. Tshebetso ya Ketane: Ketane e sebetsa e le karolo ya ho hula ya conveyor. Sistimi ya ho tlotsa e iketsang e kentswe ketane ho netefatsa hore manonyeletso ohle a tsamayang a fumana setlolo se nepahetseng.

4. Li-hangers: Li-hangers li tšehetsa ketane 'me li jara mojaro oa lintho tse tsamaisoang litseleng. Moralo oa tsona o khethoa ke sebōpeho sa likarolo tsa mosebetsi le litlhoko tse itseng tsa ts'ebetso. Li-hack tse holim'a li-hangers li fuoa kalafo e loketseng ea mocheso ho netefatsa hore li mamella tšebeliso e telele ntle le ho petsoha kapa ho senyeha.

Sistimi ena ea ho fetisa thepa e ntlafatsa katleho ea ts'ebetso le ts'epo lits'ebetsong tse fapaneng tsa indasteri.

Nako ea poso: Phupu-25-2025