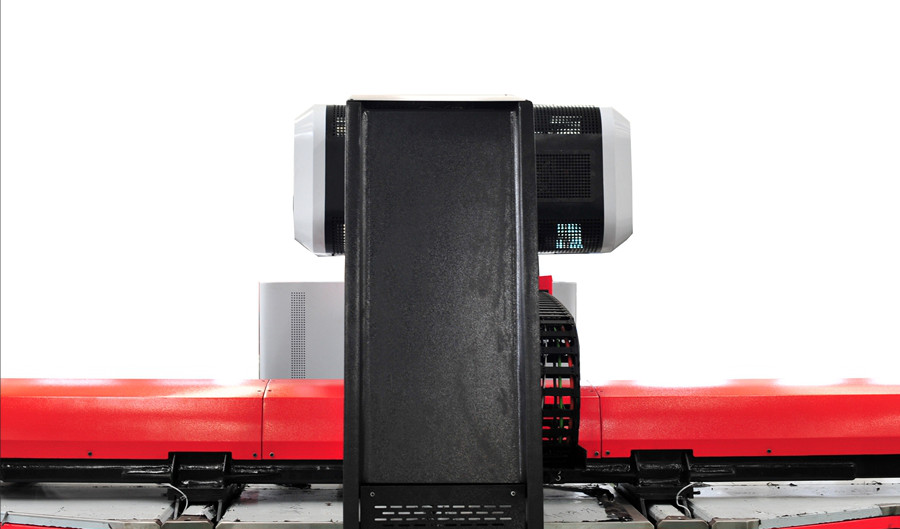

Mochini oa boleng bo phahameng oa CNC Turret Punch

1. Sistimi e le 'ngoe e tsamaisoang ke servo motor, e amohela torque e kholo e tsamaisoang ka kotloloho ea servo motor le yuniti ea ho khanna e nang le matla a holimo ho bona tšebeliso e tlase ea matla, ts'ebetso e phahameng ea phetisetso, ts'ebetso e tšepahalang le tlhokomelo e bonolo.

(1) Lebelo le feto-fetohang le stroke

a. Punch stroke e ka khethoa ho latela botenya ba lakane ka bo eona, ho ntlafatsa katleho ea mosebetsi.

b. Lebelo la punch lea fetoha nakong ea ntlha ka 'ngoe ea seteishene se seng le se seng,

c. mochine o ka lemoha lebelo le phahameng ka potlako nakong ea ho matha ho se nang letho le lebelo le tlaase nakong ea punch ea sebele, ka tsela ena, boleng ba punch bo ka ntlafatsoa ka katleho, 'me ha e le hantle ha ho na lerata nakong ea punch.

(2). Sistimi e na le ts'ireletso ea nako e telele le lisebelisoa tsa ts'ireletso tse ngata haholo.

(3). Matla a punch a ka fetoloa ka bo eona ho latela botenya ba lakane le lebelo la ho matha la pheleu ho etsa hore boleng ba ho phunya bo fihle boemong bo phahameng.

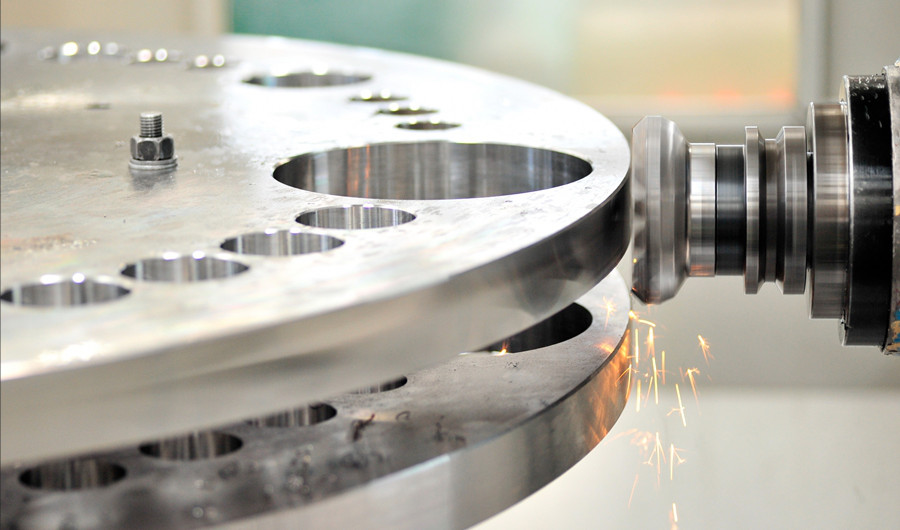

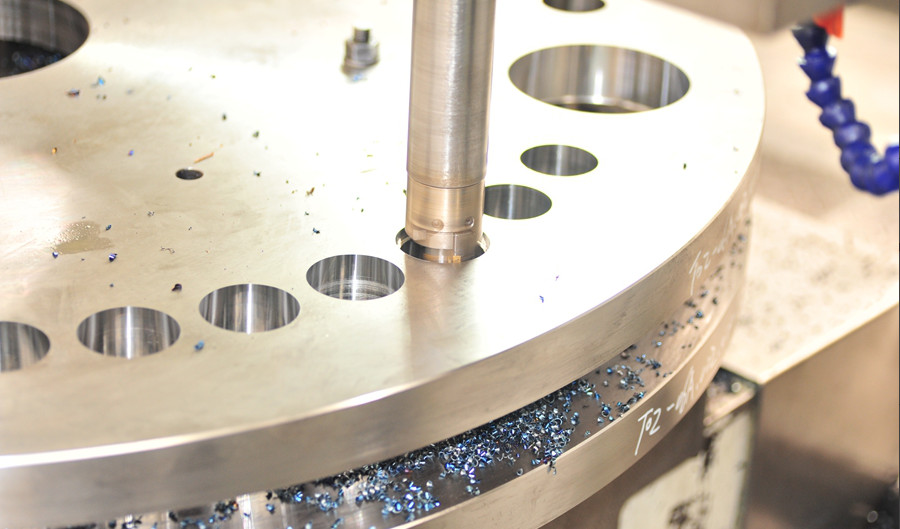

2. Turret e nang le bushing e sebetsa ka bobeli

Turret e sebetsoa ke sesebelisoa se ikhethileng ho netefatsa hore coaxiality ea turret e holimo le e tlase le ho holisa bophelo ba ts'ebeletso ea lisebelisoa; turret ea bushed e nolofatsa sebopeho sa turret ho lelefatsa bophelo ba ts'ebeletso; lisebelisoa tse telele li ka sebelisoa ho eketsa ho nepahala ho tataisang le ho atolosa bophelo ba tšebeletso ea lisebelisoa (bakeng sa lakane e teteaneng).

3. Likarolo tse tsoang linaheng tse ling tsa pneumatic, lubricating le motlakase li netefatsa ho tšepahala ha mochine oohle.

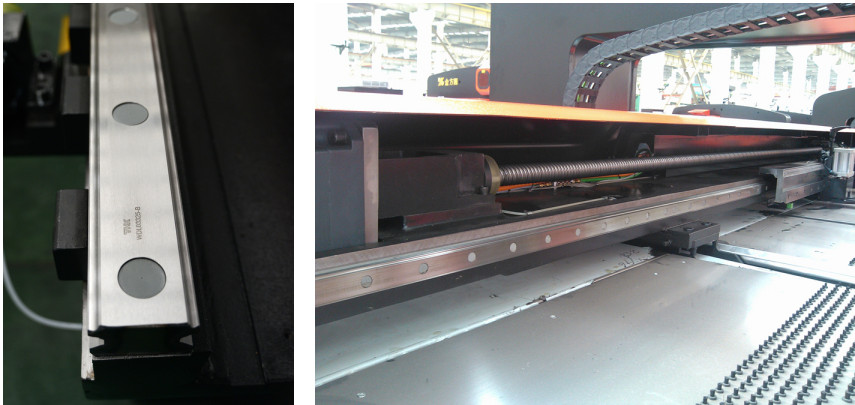

4. Tsela e kholo ea tataiso le li-ballscrew tse tsoang Japane kapa Jeremane li tiisa hore ho fepa ho nepahetse.

5. Borashe bo thata le bolo e tsoakiloeng worktable e fokotsa lerata le ho thothomela nakong ea ho matha hape e sireletsa lakane holim'a.

6. O-mofuta welded foreime e se e thothomela ka makhetlo a mabeli, khatello ea kelello e hlakotsoe ka ho feletseng. Foreimi e sebetsoa ke setsi sa tšebetso sa Jeremane SHW dual-side pentahedron processing ka nako e le 'ngoe, ha ho hlokahale hore u behe sebaka sa bobeli.

7. Letlapa le phaphametseng le nang le matla a maholo a ho thibela ho tiisa ho fepa ho tsitsitseng; kariki e kopantsoeng e tiisa ho tiea ho hoholo le motsamao o bonolo oa clamp.

8. Sistimi e hlahisoa ka ts'ebetso ea ts'ireletso ea clamp e ikemetseng ho qoba tšenyo ea lisebelisoa le clamp, ho netefatsa ts'ebetso e tsoelang pele ea lenaneo.

9. Auto-index e nka lebili le phahameng le nepahetseng la seboko le mochini oa seboko, ho netefatsa indexing e phahameng e nepahetseng. The Max. bophara ba lisebelisoa bo ka fihla ho 88.9mm mme index ea auto e ka atolosoa ho 4 nos.

10. Mohaho o kopantsoeng oa maballo ho etsa hore lekareche le bem e be karolo e le 'ngoe, ho eketsa ho tiea le ho tlisa boemo bo nepahetseng. Mochini o ka sebetsa ka mokhoa o tsitsitseng haholo nakong ea ho fepa ka lebelo le phahameng mme o felisa ho kheloha ha lilepe tsa X le Y.

11. X axis: e nka servo motor ho khanna sehlopha sa libolo tse nepahetseng hantle 'me koloi e hlahisoa ka mokhoa o tsitsitseng le o bobebe. Y axis: servo motor e khanna ka kotloloho rack ea ho fepa e hokahaneng le seporo sa mochini, sefate sa mofuta o arohaneng se ts'oaroe ka rack ea ho fepa, 'me matla a ts'ebetso a tla fetisetsoa mochining oa mochini le fatše ka rack ea ho fepa le setataiso ho fokotsa ho thothomela ha borona. Sebopeho sena se hlahisoa ka litšobotsi tsa ho tiea hantle, boima bo bobebe, matla a khoheli a tlaase, le karabelo e ntle ea matla tsamaisong eohle ea phepo, ho matha ho tsitsitseng le ho nepahala hantle.

12. Sistimi e bohareng ea lubrication e amoheloa ho romela mafura a lubrication sebakeng se lekanyelitsoeng sa lubricating ka kotloloho, ho fokotsa likhohlano tsa lipara tse ling le tse ling tse sebetsang le ho eketsa bophelo ba ts'ebeletso.

13. Anti-sheet-deformation switch le sheet-anti-stripping switch e amoheloa.

| Che. | Lebitso | Qty. | Ela hloko |

| 1 | Lenane la ho paka | 1 sete | |

| 2 | Setifikeiti sa Boleng | 1 sete | |

| 3 | Bukana ea Ts'ebetso ea Mechini | 1 sete | |

| 4 | Buka ea Ts'ebetso ea Motlakase | 1 sete | |

| 5 | Setšoantšo sa motheo | 1 sete | |

| 6 | Setšoantšo sa Motlakase oa Motlakase | 1 sete | |

| 7 | Litokomane tsa Tsamaiso ea Software ea Auto-program | 1 sete | |

| 8 | Setšoantšo sa Motlakase oa Motlakase oa DBN | 1 sete | |

| 9 | Buka ea lisebelisoa | 1 sete | |

| 10 | Buka ea tsamaiso ea CNC | 1 sete | |

| 11 | Tooling Drawing | 1 sete |

| Che. | Lebitso | Lekhalo | Qty. |

| 1 | Spanner e nang le lihlooho tse peli | 5.5×7-22×24 | 1 sete |

| 2 | Spanner e sisinyehang | 200 | 1 no. |

| 3 | Socket Head Spanner | S1.5-S10 | 1 sete |

| 4 | Cross Screwdriver | 100×6 | 1 no. |

| 5 | Grease Gun | HS87-4Q | 1 no. |

| 6 | Tlosa Lubrication Pump Compressor Gun | SJD-50Z | 1 no. |

| 7 | Sethunya sa khatello e phahameng | 1 sete | |

| 8 | T sebopeho sa kotola | M14×1.5 | 1 no. |

| 9 | Phetoho ea ho atamela | M12 PNP SN=2 bula | 1 sete |

| 10 | Phetoho ea ho atamela | M12 PNP SN=2 haufi | 1 no. |

| 11 | Spanner | T09-02,500,000-38 | 1 no. |

| 12 | Spanner bakeng sa switch cylinder ea khase | 1 sete | |

| 13 | Peipi e bonolo | Ø 12 | 1 no. |

| 14 | Pini e bonolo ea peipi | KQ2H12-03AS | 1 sete |

| 15 | Likarolo tsa motheo | 1 no. |

| Che. | Lebitso | Lekhalo | Qty. | Ela hloko |

| 1 | Boto ea lisebelisoa tsa ho koala | 3 lintlha. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Clamp portective board | 6 lintlha. | T02-20A.000.000-09C Kapa T02-20A.000.000-23A | ||

| 2 | Spring Small screw in clamp | M4x10 | 20 lintlha. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | Sekurufu ka har'a clamp | M8 x 1 x 20 | 20 no. | |

| 4 | Lehare la ho kuta | 30T | 2 lintlha. | T09-16.310,000-0.1.2 |

| 5 | Sekurufu sa ka hare | M8 x 1 x 20 | 4 lintlha. |

Sistimi ea FANUC CNC ke sistimi e ikhethileng ea CNC e ntlafalitsoeng ke Japane FANUC haholo-holo ka sepheo sa ho kopana le likarolo tsa mofuta ona oa mochini, ho ntlafatsa ts'epo ea mochini ho isa tekanyong e kholo.

Ke, Litšobotsi tsa Sisteme

1. Mosebetsi oa Graphic le punch;

2. Lenaneo le bonolo la G code bakeng sa ts'ebetso e bonolo;

3. Boema-kepe bo tloaelehileng ba RS232 ho buisana le komporo ha bonolo;

4. E tsoetseng pele e feletseng ea digital servo motor le servo system;

5.10.4 ″ Pontšo e mebala-bala ea LCD;

6. Pulse encoder semi-loop feedback;

7. Mohopolo oa EMS: 256K;

8. Lenaneo la tšimo, lenaneo la ofisi;

9. Pontšo ea Sechaena le Senyesemane;

10. Mosebetsi oa papiso ea litšoantšo;

11.Karete e le 'ngoe e kholo ea PCMCIA bakeng sa bekapo ea paramethara ea tsamaiso, ho taka lere le lenaneo la ho sebetsa, le ho hlokomela ts'ebetso ea inthanete ea lenaneo le leholo la ts'ebetso ea bokhoni;

12. Keketseho ea yuniti e nyane ka ho fetisisa, taolo ea lipapatso tsa servo ho lemoha lebelo le holimo le ts'ebetso e nepahetseng e phahameng;

13. Konopo ea ts'ebetso ho phanele e ka hlalosoa ho ea ka tlhokahalo ea sebele;

14. Super high speed clutch data lik'hebole tse nang le khokahanyo e nyenyane ea cable;

15. Ho kopanya ho phahameng, software e khethehileng. Nako e khuts'oane ea ho qala, data e ke ke ea lahleha haeba matla a haelloa ke phepelo ka tšohanyetso;

16. Ho boloka likarolo tsa 400 tsa lenaneo.

1. Li-axes tsa linear: X, Y axes, li-axes tse pota-potileng: T, li-axes tsa C, li-punch axis: Z axis;

2. Alamo bakeng sa phoso ea motlakase joalo ka setorouku se fetelletseng.

3. Mosebetsi oa ho itlhahloba.

4. Mosebetsi oa moeli o bonolo.

5. Universal G khoutu bakeng sa lenaneo;

6. Mosebetsi oa matšeliso a lisebelisoa;

7. Mosebetsi oa puseletso ea sebaka sa screw;

8. Mosebetsi oa matšeliso a fapaneng le lekhalo;

9. Mosebetsi oa ho kheloha ha likhokahano;

10. Mosebetsi oa reposition;

11. Mosebetsi oa AUTO, MANUAL, JOG mode;

12. Mosebetsi oa tšireletso ea clamp;

13. Mosebetsi oa senotlolo sa ngoliso ea ka hare;

14. Mosebetsi oa lenaneo la parameter;

15. Mosebetsi oa lenaneo-potlana;

16. Mosebetsi oa ho potlaka ho beha maemo le senotlolo sa punch;

18. Mosebetsi oa M khoutu;

19. Lenaneo le felletseng le la keketseho;

20. Conditioning, tlola ntle le maemo.

Kenyelletso ea software ea ho hlophisa

Re amohela CNCKAD ho tsoa ho Khamphani ea METALIX. Software ke sete e felletseng ea software ea othomathiki ea CAD/CAM ho tloha ho moralo ho isa tlhahisong. Ka taolo ea laeborari ea hlobo, ts'ebetso ea khetho ea othomathike, ts'ebetso ea tsela le mesebetsi e meng, e ka hlahisoa ka bo eona ke lits'ebetso tsa ts'ebetso ea CAD. U ka fihlela karolo e le 'ngoe ea lenaneo, ho iketsetsa sehlaha le sephutheloana se feletseng.

Mosebetsi oa Grafiken e matla ea DrawingCNCKAD, e bonolo ebile e bonolo ho e sebelisa, ntle le ts'ebetso e tloaelehileng ea ho taka ho latela litšoaneleho tsa tšepe ea lakane, e ekelitse mekhoa e meng e khethehileng ea ho taka e kang ho cheka, ho pota-pota, kgutlotharo, lehlakoreng le letona le sebopeho sa contour, ho luba, ho hlahloba ho hlophisa le ho lokisa ka mokhoa o itekanetseng, ho itšeha kapa ho hatakela, litlhaku tsa Sechaena DXF/IGES/CADL/DWG file input joalo-joalo.

b) Mosebetsi oa ho Tebela

E hlahisoa ka punch ea othomathiki, hlobo e khethehileng, indexing ea othomathiki, phalliso ea othomathiki, ho seha moeli, le mesebetsi e meng.

c) Mosebetsi oa ho kuta

Lekola li-contour tsa othomathike le ho lokisa liparamente tsa mofuta oa thepa, botenya, sehiloeng se le seng, sehiloeng le ho fallisoa ha ho kuta, le lits'ebetso tse ling, ts'ebetso ea ho kuta ka bohona.

d) Post Processing

Ts'ebetso ea othomathiki kapa e sebetsanang e akaretsa ts'ebetso eohle: ho hatakela, laser, plasma, mollo, ho seha metsi le ho sila.

Ts'ebetso e tsoetseng pele ea poso e ka hlahisa mefuta eohle ea khoutu ea NC e sebetsang, subroutine ea ts'ehetso, lenaneo la macro, joalo ka ho ntlafatsa tsela ea lisebelisoa le ho potoloha ha hlobo e nyane, ente ea tšehetso, ts'ebetso ea mochini oa vacuum suction joalo ka sekhahla sa thepa le sekhahla sa li-sliding block.

Ho fetisetsa lenaneo ho mochine o mong ho hloka feela ho penya ha 'maloa ka mouse.Tsena li nkiloe ho CNCKAD post processing way, ka ho felisa lifaele tse feteletseng tsa k'homphieutha tse etsang hore ts'ebetso e sebetse haholoanyane.

e) CNC Ketsiso ea litšoantšo

Software e ts'ehetsa papiso efe kapa efe e hlakileng ea lenaneo la CNC, ho kenyelletsa le khoutu ea CNC e ngotsoeng ka letsoho, ts'ebetso ea ho hlophisa e bonolo haholo, software e ka itlhahloba ka bo eona liphoso, joalo ka li-parameter tse lahlehileng le liphoso tsa sebaka, joalo-joalo.

f) Phetoho ho tloha ho NC ho ea ho Drawing

E ngotsoe ka letsoho kapa khoutu e 'ngoe ea NC, e ka fetoloa feela hore e be likarolo tsa litšoantšo.

g) Tlaleho ea Letsatsi

E ka hatisa tlaleho ea data, ho kenyelletsa le tlhahisoleseling eohle joalo ka palo ea likarolo, ho sebetsana le tlhahisoleseling joalo ka nako, sebopeho sa hlobo, joalo-joalo.

h) Phetiso ea DNC

Ho amohela sebopeho sa Windows sa mojule oa phetisetso, e le hore phetisetso lipakeng tsa PC le lisebelisoa tsa mochini e be bonolo haholo.

1) 、 Tšehetsa mefuta eohle ea hona joale ea CNC turret punch, mochini oa ho itšeha oa laser, mochini oa ho itšeha oa plasma le mochini oa ho itšeha lelakabe le lisebelisoa tse ling tsa mochini.

2) 、 Ts'ehetsa ts'ebetso eohle ea ts'ebetso ea lisebelisoa tsa CNC, ho kenyelletsa ho taka, ts'ebetso ea othomathiki kapa e sebetsanang le ts'ebetso, ts'ebetso ea poso, lenaneo la papiso ea CNC, ho itšeha ka matsoho le ho jarolla, ho jarolla le ho kenya faele ea NC joalo-joalo.

3)), E ka kenya ka ho toba Autocad, SolidEdge, SolidWork le CadKey joalo-joalo ho kenyelletsa lifaele tsohle tse tummeng tsa CAD tse hlahisitsoeng ke litšoantšo.

4) 、Software e ts'ehetsa lisebelisoa tse fapaneng tsa taolo ea lipalo, e ka beha likarolo tsa NC ho hlahisa lifaele tsa lisebelisoa tse fapaneng, bakeng sa lisebelisoa tse ngata ka nako e le 'ngoe nakong ea ts'ebetso.

Ho Bea Maemo ka Othomathike

Ha boholo ba poleiti bo le boholo ho feta mefuta e meng e fapaneng, mochine o ikemela hape, ebe o iketsetsa litaelo tsa ho beha maemo; haeba mosebelisi a na le litlhoko tse ikhethang, a ka fetoloa kapa a hlakoloa ka litaelo tsa bona tsa ho beha maemo.

Ho qoba ho thipa ka tsela e iketsang

Litaelo tse hlahisoang ke ho beha maemo ka bo eona ho ka etsang hore clamp e qobe sebaka se shoeleng, e fokotse litšila; hore na poleiti ke karolo kapa likarolo tse 'maloa tsa poleiti ea tšepe, e ka lemoha ts'ebetso ea ho qoba ho koala.

Ts'ebetso ea ho hlobola

E le ho fokotsa deformation ea lintho tse bonahalang tshebetsong ea setempe, mokhoa oa ho hlobolisa thepa ea ho hlobolisa e ka amoheloa, 'me sesebelisoa sa ho itšeha se ka sebelisoa ka pele kapa ka morao ea taelo ea lekala.

Mokhoa oa ho faola limela

E kopantsoe le mosebetsi oa ho otla ka bohale ka mokhoa o tloaelehileng, ho phunya ka mokhoa o itekanetseng o khonang ho phunya thepa e robehileng ho pota-pota.

Ho khutsa ho le mong ho itsamaela

Ka mochini oa clamp o tsamaeang o ka hlahisoa ke software ka bo eona e tsamaisang clamp ka litaelo tsa NC.

Minimun die rotation

Khetho e tlase ea ho potoloha ha die e ka fokotsa ho roala ha seteishene sa indexing sa othomathike le ho ntlafatsa ts'ebetso ea tlhahiso.

Mosebetsi oa Mefuta e mengata ea ho Punch

Mosebetsi oa ho phunya khutlotharo, ho phunya bevel, ho phunya li-arc le mokhoa o mong o ikhethang oa ho phunya.

Mosebetsi oa ho Koetlisa ka Boiketsetso ka Matla

Likarolo tsa Automatic Punching li kenyelletsa khokahano ea othomathike ea micro, khetho e bohlale ea hlobo le leruo la ho lemoha alamo le mesebetsi e meng.

I) Mosebetsi oa ho itšeha o iketsang

METALIX CNCKAD e na le karolo ea AutoNest e leng sete ea lisebelisoa tsa 'nete tsa ho etsa sehlaha ka mokhoa o ikemetseng, tse ka hlokomelang ts'ebetso eohle ea tšepe ea mokhoa oa tekheniki.

1. Phepelo ea moea: khatello e lekantsoeng ea ho sebetsa e lokela ho ba ho feta 0.6mPa, phallo ea moea: ho feta 0.3m3 / min.

2. Matla: 380V, 50HZ, matla a feto-fetoha: ± 5%, matla a motlakase a 30T ke 45KVA, bophara ba cable bo matla ke 25mm², breaker ke 100A. Haeba motlakase o sa tsitsa, ho hlokahala hore ho be le stabilizer, haeba ho e-na le ho tsoa ha motlakase, tšireletso e hlokahala.

Oli ea 3.Hydraulic: (SHELL) Tonna T220, Kapa oli e 'ngoe bakeng sa setlolo sa tataiso le seporo.

Oli ea ho tlotsa: 00 # -0 # Khatello e feteletseng ea mafura (GB7323-94), tlhahiso: ka tlase ho 20 ° C sebelisa 00 # Khatello e feteletseng ea mafura, ka holimo ho 21 ° C sebelisa 0 # Khatello e feteletseng ea mafura

| Brand | Lebitso | Litlhaloso | Mocheso |

| Khetla | EPO | 0# Mafura a khatello e feteletseng | 21°C holimo |

| Khetla | GL00 | 00 # Khatello e feteletseng ea mafura | 20°C ka tlase |

3. Mocheso oa tikoloho: 0°C - +40°C

4. Mongobo oa tikoloho: mongobo o lekanyelitsoeng 20-80%RH(un-condensation)

5. Qoba hole le ho thothomela ho matla kapa ho kena-kenana le electromagnetism

6. Tikoloho e nang le lerole le lenyenyane, ha ho na khase e chefo

7. Lokisetsa motheo ho latela setšoantšo sa motheo

8. Mosebedisi o lokela ho kgetha setsebi sa theknishiene kapa moenjinere bakeng sa kwetliso, semelo sa thuto seo bonyane a lokelang ho qeta sekolong sa sekondari sa botekgeniki, mme a se hlophise bakeng sa nako e telele.

11.O tlameha ho lokisa motheo ho latela setšoantšo

12. Sekoahelo se bulehileng sa 65mm spanner, molamu o tšehetsang afterburner, ho lokisa boemo ba motheo.

13. Ho feta lilithara tse 5 tsa peterole e hloekileng, likotoana tse ngata, sethunya, oli e tlotsang, hoo e ka bang lilithara tse 1 bakeng sa lisebelisoa tsa mochini oa ho hlatsa le hlobo.

14 e nang le Ф10 * 300 e le 'ngoe le lithupa tsa koporo tsa Ф16*300 bakeng sa ho kenya hlobo. Beam e telele (fuselage le beam li phuthetsoe ka thoko, empa hape le ho lokisa likarolo tse romelloang)

15 sesupo sa ho daela (0-10mm range), se sebelisetsoang ho lokisa axis ea X le Y perpendicularity.

16 ha lisebelisoa li fihla fekthering, lokisa sephethephethe sa 20T kapa crane bakeng sa lisebelisoa tsa ho phahamisa

17.Haeba V axis e na le enjene ea chiller ea metsi, median e amanang le pholiso e tlameha ho lokisoa, molumo ke 38L.

Litaba tse ling tse sa buuoeng li hloka tlhaloso e eketsehileng le khokahanyo

Mochini oa CNC Turret Punch Machine mochini;nomerical control turret punch press;servo drive turret punch press;turret punch press

| Che. | Tlhaloso | Yuniti | Moetso oa Mochini | ||

| MT300E | |||||

| 1 | Max. Punch Force | kN | 300 | ||

| 2 | Mofuta o ka Sehloohong oa ho Khanna | / | E tsamaisoa ka mochini o le mong | ||

| 3 | Sistimi ea CNC | / | Sistimi ea FANUC CNC | ||

| 4 | Max. Boholo ba Ts'ebetso ea Leqephe | mm | 1250*5000 (ka sebaka se le seng) | 1500 * 5000 (ka sebaka se le seng) | |

| 5 | No. ea Clamp | che. | 3 | ||

| 6 | Max. Ho sebetsa Botenya ba Leqephe | mm | 3.2/6.35 | ||

| 7 | Max. Punch Diameter ka Nako | mm | Φ88.9 | ||

| 8 | Main Strike Stroke | mm | 32 | ||

| 9 | Max. Punch Hit ka lebelo la 1mm | hpm | 780 | ||

| 10 | Max. Punch Hot ka lebelo la 25mm | hpm | 400 | ||

| 11 | Max. Lebelo la ho Nibbling | hpm | 1800 | ||

| 12 | Nomoro ea Repositioning Cylinder | beha | 2 | ||

| 13 | No. ea Seteishene | che. | 32 | ||

| 14 | Nomoro ea AI | che. | 2 | ||

| 15 | No. ea Laola Axis | che. | 5(X,Y,V,T,C) | ||

| 16 | Mofuta oa lisebelisoa | / | Mofuta o molelele | ||

| 17 | Mofuta o sebetsang | / | Ka tlase ho 3.2mm: Brush e felletseng e sebetsa hantle (Ho phahamisa libolo bakeng sa ho laela ho ka eketsoa e le khetho) | ||

| Ka holimo ho 3.2mm: Full libolo worktable | |||||

| 18 | Max. Lebelo la ho fepa | X Axis | m/m | 80 | |

| Y Axis | 60 | ||||

| XY e kopantsoe | 100 | ||||

| 19 | Turret Lebelo | rpm | 30 | ||

| 20 | Tooling Rotation Speed | rpm | 60 | ||

| 21 | Ho nepahala | mm | ±0.1 | ||

| 22 | Max. Mojaro Bokhoni | Kg | 100/150 bakeng sa bolo ea worktable | ||

| 23 | Matla a Motlakase | kVA | 45 | ||

| 24 | Mokhoa oa ho sebetsa | / | mofuta o ikemetseng oa ho qhaqholla | ||

| 25 | Khatello ea Moea | MPa | 0.55 | ||

| 26 | Tšebeliso ea Moea | L/ mets | 250 | ||

| 27 | Bokhoni ba Memori ea CNC | / | 512k | ||

| 28 | Thibela ho fumana libaka tse shoeleng | / | Y | ||

| 29 | Sheet-anti-stripping Switch | / | Y | ||

| 30 | Anti-Sheet-Deformation Switch | / | Y | ||

| 31 | Bophahamo ba Outline | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Che. | Lebitso | Brand | Lekhalo | ||

| 1 | Sistimi ea CNC | FANUC | OI-PF | ||

| 2 | Servo Driver | FANUC | AISV | ||

| 3 | Servo Motor (X/Y/C/T axis) | FANUC | AIS(X,Y,T,C) Enjene e khethehileng bakeng sa V axis | ||

| 4 | Tataiso | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | Ballscrew | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Precise Bearing | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Likarolo tsa moea | Mahlakore a mararo | SMC | AC30A-03D | |

| Solenoid valve | SY5120-5D-01 | ||||

| Moferefere | AN10-01 | ||||

| Silinda | CP96SDB40-80-A93L | ||||

| 8 | Sistimi ea Motlakase | Seqhenqha | Schneider | / | |

| Ikopanye | Schneider | / | |||