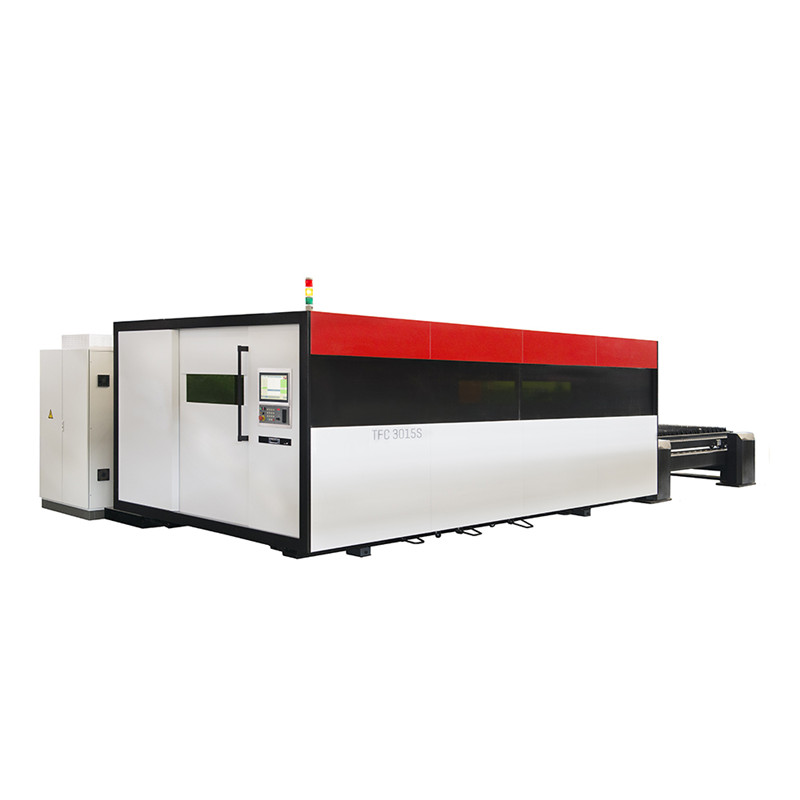

CNC Fiber Laser Cutting Machine

Mochini oa ho itšeha oa EFC3015 CNC oa laser o sebelisoa haholo-holo bakeng sa ho itšeha le ho sebetsa poleiti e bataletseng, ka sistimi ea CNC, mohala o otlolohileng le mokokotlo oa sebopeho se ikemetseng o ka seha le ho betloa ka poleiti. E ka seha poleiti e tloaelehileng ea tšepe ea carbon, poleiti ea tšepe e sa hloekang, poleiti ea koporo, koporo e mosehla le aluminium, le tšepe e 'ngoe e ke keng ea seha habonolo ka mokhoa o tloaelehileng oa ho sebetsa.

EFC3015 CNC laser ho itšeha mochini ke mofuta o mocha oa ho itšeha ka laser. Sebopeho se na le ho tiea ho hoholo, botsitso bo botle, ts'ebetso e phahameng ea ho itšeha le ho nepahala ha machining. Lihlahisoa ke tsa maemo a holimo, polokeho, ts'ebetso e bonolo le tšebeliso e tlase ea matla. Ke ea sehlahisoa sa ts'ireletso ea tikoloho, boholo ba poleiti e sebetsitsoeng: 3000 * 1500mm; e nang le thebe ea tšireletso le tafole ea shuttle. Sebopeho ka kakaretso se kopane ebile sea utloahala.

Tšebeliso e tlaase - laser ha e hloke khase;

Tšebeliso e tlaase ea matla, ho boloka matla, tšireletso ea tikoloho, tšebeliso e tlaase ea matla;

Sebopeho sa modular, tsamaiso ea ho pholisa le tsamaiso ea mohloli oa leseli le mohloli oa laser li kopantsoe hammoho;

Botsitso bo phahameng - matla - tsamaiso ea ho laola maikutlo a nako ka matla a laser, botsitso ba matla 1%;

Litšenyehelo tsa tlhokomelo li tlase - hlooho ea fiber e sebelisa theknoloji ea tšireletso ea seipone, haeba e silafetse, e hloka feela ho fetola lense ea tšireletso;

A. e amohela tataiso e nepahetseng e romelloang kantle ho naha, e kenya mochini o nepahetseng oa li-gear, ho netefatsa boemo bo nepahetseng le bo pheta-phetoang.

B. Gantry mofuta oa dual motor direct drive structure e etsa hore sebopeho sohle sa sehlahisoa se kopane, 'me ho tiea ho hotle,' me bophahamo ba mochine oohle bo tlaase.

'Mele o ka sehloohong o entsoe ka lipoleiti tsa tšepe, ka mor'a mochine o thata, o sebetsanang le khatello ea kelello ea botsofali. Ka machining e nepahetseng, e fana ka sethala se tiileng le boemo ba sistimi ea motsamao.

Beam e amohela sebopeho se feto-fetohang, se nang le katoloso ea mocheso o feto-fetohang le ts'ebetso ea ho honyela, accounting ka mokhoa oa finite element. Likarolo tsa Beam li behiloe betheng ka tataiso e nepahetseng. Tataiso, lisebelisoa le rack li na le sekoaelo se bonolo sa tšireletso, e le ho qoba ho silafatsoa ke lerōle.

Sehlahisoa se na le sesebelisoa sa shuttle se sebetsang, se bonolo ho se jarisa le ho laolla thepa ha se seha. Ka tlase ho sebaka sa ho sebetsa se nang le likarolo tsa karohano ea lerōle le li-groove tsa ho bokella thepa, tse tsamaellanang le koloi e lahlang mabili, likhechana li ka kena ka kotloloho ka koloing e lahlang litšila.

Fiber laser e na le litšobotsi tsa haufi le infrared spectroscopy, boleng bo botle ba boriti, phetisetso ea fiber ea optical, ts'ebetso e phahameng ea phetoho ea electro-optical joalo-joalo.

(1) Ka ts'ebetso ea pontšo ea lebone le khubelu la laser.

(2) Ts'ebetso e phahameng ea phetoho ea elektro-optic: katleho ea phetoho ea fiber laser electro-optic e ka bang 33%.

3

(4) Ts'ebetso e phahameng, sesebelisoa sa ho futhumatsa ka hare se tlase haholo ha se bapisoa le laser ea setso, tlhoko ea matla a motlakase le pholiso e fokotsehile haholo.

5

(1) Sistimi ea taolo ea CNC e sebelisa Windows 7system, ts'ebetso e tsitsitse ebile e ka tšeptjoa.

(2) Torque e kholo ea AC digital servo motor ho netefatsa hore boemo ba sehlahisoa bo nepahetse le ts'ebetso e matla.

(3) Ketsiso ea litšoantšo.

(4) mosebetsi oa ho laola matla.

(5) Mosebetsi oa Leapfrog.

(6) Ho khaola mosebetsi oa ho hlahloba.

(7) Ts'ebetso e matla ea ts'ebetso.

(8) Mosebetsi oa khefutso, o tlaleha karolo ea ts'ebetso ka bo eona.

(9) Tlhahlobo ea lenaneo la NC e ka fetoloa ka nako ea sebele ho fetola mokhoa oa ho hlophisa.

(10) Fetola, fetola litaelo leha e le life ts'ebetsong ea lenaneo la ho batla ho..

(11) ts'ebetso ea ho itlhahloba, mokhelo oa alamo o bonts'oa sebopeho sa ts'ebetso.

(12) Boholo ba mosebetsi oa matsoho bo ka atolosoa le ho fokotseha.

(13) Mosebetsi oa ho sebetsana le setšoantšo sa workpiece.

(14) Mosebetsi oa ho batla o ikemetseng.

(15) Ka mor'a hore motlakase o tima, li-coordinate tsa hona joale li ka rekotoa 'me tsa tsosolosoa ka mor'a hore motlakase o bulehe.

Lebone la laser le entsoe ka fiber ea optical, 'me lebone la laser le bapa le lense e shebileng. Lense e sireletsang e kentsoeng setulong sa seipone sa "pull type", nako ea tlhokomelo le e ncha e khutšoanyane haholo. Khetha hlooho ea laser e nang le sensor e sa amaneng le capacitive, ts'ebetso e tsitsitse ebile e ka tšeptjoa, ho bonolo ho e sebelisa.

Likarolo ke tse latelang:

(1) Tšebeliso ea lilense tse sireletsang tsa mofuta oa li-drawer ho thusa ho nkela sebaka se potlakileng sa lilense tse sireletsang tsa optical bakeng sa ts'ireletso ea lense ea collimator le lense e tsepamisitseng maikutlo.

(2) Hlooho ea ho itšeha e na le sesebelisoa sa ho latela bophahamo ba Z axis se laoloang ke sensor ea capacitive e sa amaneng le eona. Nakong ea ho itšeha, boemo bo lekanyelitsoeng pakeng tsa thapo ea laser le poleiti e ka fetoloa ka tsela e iketsang ke sebaka se pakeng tsa bokaholimo ba sesebediswa le nozzle.

(3) Hlooho ea ho itšeha ka laser e ka fana ka sistimi ea CNC ka lets'oao la ho bula mohala le ho thulana ha hlooho, joalo-joalo.

(4) Khatello ea khase ea 2.5 MPa e ka ba tlas'a ho khaola lisebelisoa tsa ho sebetsa tse kang tšepe e sa hloekang.

(5) Metsi a pholileng, ho khaola khase e thusang, li-sensor, joalo-joalo kaofela li kopantsoe hloohong ea ho itšeha, ka katleho ho fokotsa tšenyo ea likarolo tse ka holimo ho ts'ebetso ea ho itšeha, ho ntlafatsa botsitso ba sehlahisoa.

4.Sesebelisoa sa polokeho:

Sebaka sa ts'ebetso se koaletsoe ka sekoahelo se sireletsang 'me se fanoa ka fensetere ea tšireletso ho sireletsa motho ea sebetsang mahlaseling a laser.

5. Pokello ea lerōle:

Sebaka sa ho itšeha se na le phaephe e monyang lerōle e arolang, 'me sekontiri se matla sa centrifugal se sebelisetsoa ho tlosa lerōle le lerōle. Fana ka sefofane sa moea le boholo ba sebopeho le hose ea limithara tse 3, tube ea katoloso e etsoa ke mosebedisi ho ea ka sebaka seo, bolelele ba phala ea moea bo ka tlase ho limithara tse 10, sefofane sa moea se ka ntle;

6.Bokhoni ba ho thibela tšitiso:

Ka sistimi e tsoetseng pele ea taolo ea dijithale, e na le bokhoni ba ho hanela tšitiso. Sistimi ea motlakase e nka moralo o tiileng oa anti-jamming, khabinete ea taolo ea motlakase e arotsoe ka libaka tse matla le tse fokolang, tse ka thibelang ho kena-kenana ka nepo lipakeng tsa likarolo tsa motlakase, kahoo e ka netefatsa ts'ebetso e ts'eptjoang le e tsitsitseng ea lihlahisoa.

7. Leseli:

Sebaka sa ho itšeha se na le mabone a mabeli a tšireletso a motlakase, a ka fanang ka khanya ha leseli le sa lekana kapa le hlokomeloa, ho etsa hore ts'ebetso e be bonolo haholoanyane.

8.Likarolo tsa motlakase:

Likarolo tsa motlakase tse sebelisang Schneider le lihlahisoa tse ling tse tsebahalang tsa machaba tsa Brand Company, li ntlafatsa haholo ts'epo ea ts'ebetso. Khabinete ea motlakase e amohela sebopeho se ikemetseng se koetsoeng, 'me' mala oa terata o sebelisetsoa ho khetholla AC, DC, matla le terata e sireletsang fatše.

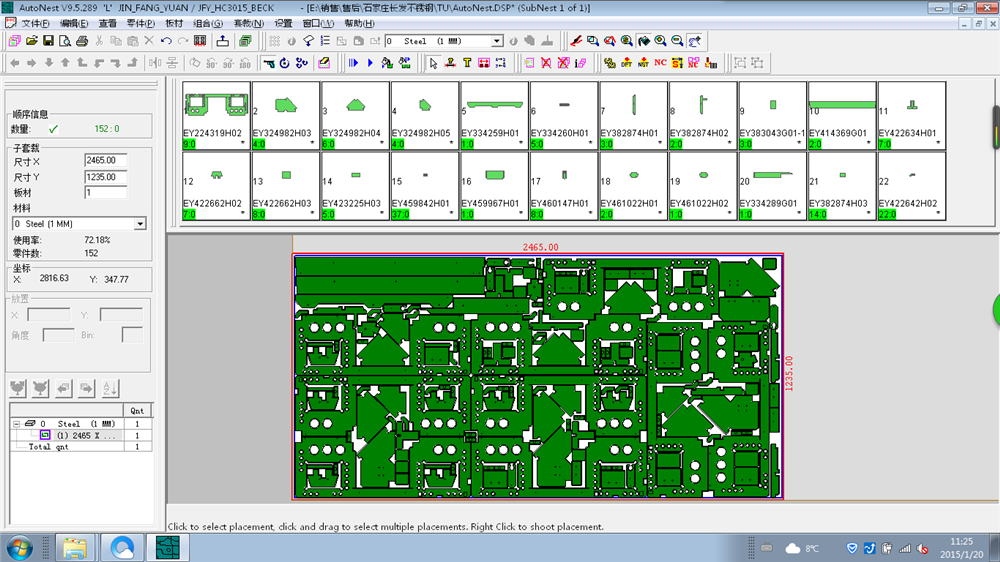

Sehlahisoa se nang le software ea ho iketsetsa lenaneo la CNCKAD, ha se feela se ka amanang le theknoloji ea CAD / CAM ea fektheri, empa hape le ho fokotsa mosebetsi oa ho etsa mananeo le monyetla oa ho etsa phoso, lenaneo le letle le ka etsisa ho itšeha. E na le mojule oa ho seha, o itokiselitse le ho hlophisoa ha likarolo tse lokelang ho etsoa. Grafiken e bonolo le e rarahaneng ea li-workpiece e ka fetoloa ka bo eona ho ba lenaneo la ts'ebetso.

Mosebetsi oa software ea NC laser cutting system:

(1) Sebopeho sohle sa Sechaena se sebetsang.

(2) Tšehetso bakeng sa DWG, DXF input le liforomo tsa tlhahiso.

(3) Ts'ebetso ea ho itlhahloba e ntle, hana ho etsa ts'ebetso ea phoso

(4) Mosebetsi oa ho iketsetsa sehlaha, ho boloka thepa.

(5) Ts'ebetso ea ho itšeha ka botlalo ka mekhahlelo e mengata.

(6) Mosebetsi oa ho betla.

(7) Mefuta e fapaneng ea fonte bakeng sa UK le Sechaena.

(8) Bolelele ba mokhoa oa ho itšeha bo ka baloa.

(9) Mosebetsi o tloaelehileng oa ho itšeha.

(10) Mesebetsi ea tsamaiso ea litšenyehelo.

(11) Ho seha database..

(12) Phapanyetsano ea data e ka etsoa ka sebopeho sa USB kapa RS232.

* Tikoloho ea ts'ebetso ea software (e khothaletsa mosebelisi ho ts'ehetsa hardware)

(1) Memori 256M

(2) Hard drive 80G

(3) XP Windows tshebetso ya ho sebetsa

(4) TFT 17 "LCD pontšo

(5) 16X DVD CD-ROM

| Ntho | Qty. | Keletso/Mofani |

| Sistimi ea CNC | 1 sete | Beck Hoff |

| Khanna | 1 sete | LUST Drive (X/Y axis)+PHASE motor (X/Y axis)+Delta drive le motor (Z axis) |

| Laser jenereithara | 1 sete | TRUFIBER KHOOA |

| X/Y axis e nepahetseng ea lisebelisoa | 1 sete | GUDEL/ATLANTA/GAMBINI |

| Z axis e nepahetseng ka ho hlaka | 1 sete | THK |

| X/Y/Z axis e nepahetseng ea tataiso ea mola | 1 sete | THK |

| Motor bakeng sa tafole ea shuttle | 1 sete | KHOTSO |

| Likarolo tsa moea | 1 sete | SMC, GENTEC |

| Hlooho e Sehang | 1 sete | PRECITEC |

| Lenaneo la Auto-program | 1 sete | CNCKAD |

| Likarolo tsa motlakase | 1 sete | Schneider |

| Towline | 1 sete | IGUS |

| Sepholi sa Metsi | 1 sete | TONGFEI |

| Che. | Ntho | Tlhaloso | Yuniti |

| 1 | Matla | 380/50 | V/Hz |

| 2 | Kabo ea motlakase e hlokahalang | 40 | kVA |

| 3 | Botsitso ba Matla | ±10% | |

| 4 | Khomphuta | RAM 256M/hard disk 80G, DVD | |

| 5 | Oksijene bakeng sa ho seha tšepe ea carbon | Bohloeki bo lokela ho ba bo phahameng ho feta 99.9% | |

| 6 | Nitrojene bakeng sa ho seha tšepe e sa hloekang | Bohloeki bo lokela ho ba bo phahameng ho feta 99.9% | |

| 7 | Metsi a pholileng a metsi (metsi a silafetseng) | 100 | L |

| Ho tsamaisa:> 25μS/cm | μs | ||

| 8 | Metsi a hloekileng | 150 | L |

| 9 | Khanyetso ya ho thella | ≤4 | Ω |

| 10 | Tlhophiso ea tikoloho mocheso oa jenereithara ea laser | 5-40 | ℃ |

| 11 | Ho kenya mongobo tikolohong ea jenereithara ea laser | Ka tlase ho 70% | |

| 12 | Tlhokahalo ea sebaka sa ho kenya (lintlha li ka fetisetsoa setšoantšong sa motheo) | Botenya ba konkreite ea motheo bo lokela ho ba botenya ho feta 250mm, botenya bo lokela ho ba tlase ho 10mm ho 3m ka ngoe. Ha hoa lokela ho ba le ho thothomela ka hare ho sebaka sa ho kenya. | |

| Ntho | Qty. | Yuniti |

| Lense e sireletsang | 5 | Khomphutha |

| Lesale la ceramic | 1 | Che. |

| Ho khaola nozzle | 6 | Che. |

| Spanner | 1 | Che. |

Fana ka litokomane tsohle tse hlokahalang le tse qaqileng tsa tekheniki bakeng sa ho kenya, ho sebetsa le ho hlokomela

(1) Litaelo tsa Mechini ea ho Seha Laser

(2) Data System CNC

(3) Setšoantšo sa molao-motheo oa motlakase

(4) Litaelo bakeng sa Lipholisa Metsi

(5) Mokhoa oa ho kenya

(6) Setšoantšo sa motheo

(7) Setifikeiti sa Tšoaneleho

(8) Ho kenya, ho laela le ho amoheloa

Kamora hore sehlahisoa se fihle sebakeng sa ts'ebetso sa mosebelisi, k'hamphani ea rona e tla hlophisa basebetsi ba nang le boiphihlelo sebakeng sa mosebelisi bakeng sa ho kenya, ho laela le ho seha le ho sebetsa sampole. Kamohelo ea ho qetela e etsoa sebakeng sa mosebelisi ho latela maemo a kamohelo a k'hamphani ea rona. Lintho tsa kamohelo li kenyelletsa: boleng ba ponahalo, tlhophiso ea karolo e 'ngoe le e' ngoe, ho nepahala le boleng, litekanyetso tsa ts'ebetso, botsitso, tlhahlobo ea ho sebetsa, joalo-joalo.

Khampani ea rona e ikarabella bakeng sa ho kenya le ho laela .Basebedisi ba hloka ho lokisa lisebelisoa tse hlokahalang tsa basebetsi le ho phahamisa lihlahisoa. Basebelisi ba lokisa lisebelisoa tse ka jeoang le lisebelisoa tsa sampole bakeng sa ho fana ka taelo.

Mohato oa pele

(1) Kamohelo ea pele ea lihlahisoa e etsoa k'hamphaning ea rona.

(2) Ho amoheloa ha lihlahisoa ho tla etsoa ho latela tumellano ea tekheniki e saennoeng ke mahlakore ka bobeli.

(3) Tlhahlobo ea ponahalo ea sehlahisoa: sebopeho sa lipeipi se lokela ho ba se utloahalang, se makhethe le se setle, se ka tšeptjoang; pente holim'a junifomo le mokhabiso o motle; ponahalo ya sehlahiswa ntle le ho kokota le mefokolo e meng.

(4) Tlhahlobo ea tlhophiso ea lihlahisoa.

(5) Tlhahlobo ea setšeng ea boleng ba sampole e sehang.

Mohato oa 2 Kamohelo

(1) Kamohelo ea ho qetela ea sehlahisoa e etsoa sebakeng sa mosebedisi.

(2) Kamohelo ea lihlahisoa e tla etsoa ho latela tumellano ea tekheniki e saennoeng le taelo ea kamohelo ea kamohelo, 'me lisebelisoa tsa tlhahlobo li tla fanoa ke mosebelisi. Haeba mosebelisi a hloka ho amohela lits'oants'o tse tloaelehileng tsa mosebetsi, ka kopo fana ka litšoantšo tse tloaelehileng (mofuta oa elektroniki) esale pele.

(3) Ka mor'a ho phethoa ha ho kenya le ho laela, haeba sehlahisoa se sebetsa ka tloaelo , se tla feta teko ea ho amohela. Teko ea ho qetela ea ho amoheloa e tla nkoa e le ea tšoanelehang 'me nako ea tiiso ea boleng e tla qala.

(1) E hloka hore barupeluoa ba be le sekolo sa sekondari kapa thuto e phahameng (tse khethehileng tsa motlakase ke tsona tse molemo ka ho fetisisa), ka nako e tšoanang, ba be le tsebo e itseng ea motheo ea k’homphieutha, ’me ba be le tsebo ea ho sebetsa ka k’homphieutha.

(2) Kamora ho kenya le ho kenya tšebetsong, k'hamphani ea rona e na le boikarabello ba ho fana ka koetliso ea mahala sebakeng sa basebelisi bakeng sa matsatsi a 7, ho koetlisa mosebeletsi a le mong oa ho lokisa motlakase, basebetsi ba 2 le mosebeletsi a le mong oa ho lokisa mechini. Hape etsa bonnete ba hore basebelisi ba ka tseba hantle tšebetso ea sehlahisoa, ho sebetsa ka nepo le litsebo tsa ho li lokisa.

(3) Likahare tsa koetliso: sebopeho sa sehlahisoa le ts'ebetso, ts'ebetso ea laser, ts'ebetso, lenaneo la NC, theknoloji ea ts'ebetso ea laser, tlhokomelo ea letsatsi le letsatsi le likarolo tse ling.

(4) Tšehetso e khethehileng ea koetliso: Basebedisi ba ka hlophisa basebetsi ba 2-3 le basebetsi ba tlhokomelo ho tla k'hamphani ea rona ka nako leha e le efe.

Koetliso ha e lefelloe litefiso tsa koetliso.

Litšenyehelo tse bakiloeng nakong ea tiisetso li tla lefelloa ke k'hamphani ea rona, ntle le tse hlahisitsoeng ka lebaka la tšebeliso e fosahetseng le ts'ebetso ea basebelisi.

Khamphani ea rona e fana ka litšebeletso tsa tlhokomelo le likarolo tse ling tsa bophelo bohle.

Nako ea netefatso ea boleng ba sehlahisoa ke selemo se le seng mme nako ea netefatso ea boleng ba lense ea optical ke matsatsi a 90. Ho seha nozzle, seha se ts'ehetsang poleiti ea leino, sefahla, 'mele oa ceramic le lense ea optical ke likarolo tse robehileng habonolo.

Tlhokomeliso: EFC e na le ts'ebetso ea ho seha moea (10 kg air compressor), empa moreki o lokela ho hlomella likarolo tse latelang a le mong.

CNC Fiber Laser Cutting Machine;cnc faeba laser cutting machine;cnc fiber laser;cnc fiber laser cutter

| Ntho | Lebitso | Brand | Mohlala | OTY |

| 1 | Compressor ea moea e se nang oli | WW-0.9/1.0 | 1 | |

| 2 | Se omisa | MOEKETSI | SPL012 | 1 |

| 3 | Searohanyi sa metsi | domnick | Setšoantšo sa WS020CBFX | 1 |

| 4 | Sefe | domnick | AO015CBFX | 1 |

| 5 | Sefe | domnick | AA015CBFX | 1 |

| 6 | Sefe | domnick | ACS015CBMX | 1 |

| 7 | Ho kopanya | MOEKETSI | FXKE2 | 2 |

| 8 | Ho kopanya | MOEKETSI | NJ015LG | 1 |

| 9 | Sephahla sa khatello ea khatello | FESTO | LR-1/2-D-MIDI | 1 |

| 10 | Kopanetsoeng | SMC | KQ2H12-04AS | 1 |

| 11 | Kopanetsoeng | SMC | Setšoantšo sa KQ2L12-04AS | 6 |

| 12 | Kopanetsoeng | SMC | KQ2P-12 | 1 |

| 13 | Peipi ea khase | SMC | T1209B | 15m |

| 14 | Kopanetsoeng | EMB | VADKO 15-RL/WD | 1 |

| 15 | Kopanetsoeng | EMB | X A15-RL/WD | 1 |

1. Tlhaloso e ka Sehloohong

| Ntho | Tlhaloso | Yuniti | |

| 1 | Boholo ba ho Seha Lakane | 3000×1500 | mm |

| 2 | Stroke ea X Axis | 3000 | mm |

| 3 | Stroke ea Y Axis | 1500 | mm |

| 4 | Stroke ea Z Axis | 280 | mm |

| 5 | Max. Lebelo la ho fepa | 140 | m/m |

| 6 | Ho Seha ho Nepaha | ±0.1 | mm/m |

| 7 | Rated Laser Power | 1000 | W |

| 8 | Botenya ba ho Seha (ha boemo bo hlokahalang ba ho itšeha bo fihletsoe) | Khabone tšepe 0.5-12 | mm |

| Tšepe e sa hloekang 0.5-5 | mm | ||

| 9 | Botenya bo tsitsitseng ba ho Seha | Carbon Steel 10 | mm |

| Tšepe e sa hloekang 4 | mm | ||

| 10 | Matla a Kena | 31 | kVA |

| 11 | Nako ea phapanyetsano ea tafole ea Shuttle | 10 | S |

| 12 | Boima ba Mochini | 8 | t |

2.SPI Laser Resonator

| Mohlala | TruFiber -1000 |

| Matla a Kena | 3000W |

| Matla a Phallo | 1000W |

| Matla a Matla a Laser | <1% |

| Laser wave length | 1075nm |

Sistimi ea 3.CNC

| Ntho | Tlhaloso |

| Sistimi ea CNC | Beckhoff |

| processor | Dual-core 1.9 GHz |

| Bokhoni ba memori ea sistimi | 4GB |

| Bokhoni ba memori ea Hardware | 8GB |

| Hlahisa mofuta oa skrine le boholo | 19 ″ kristale ea metsi a mebala |

| Boema-kepe bo tloaelehileng ba puisano | USB2.0, Ethernet |